High School Students Participate in Real STEM Research

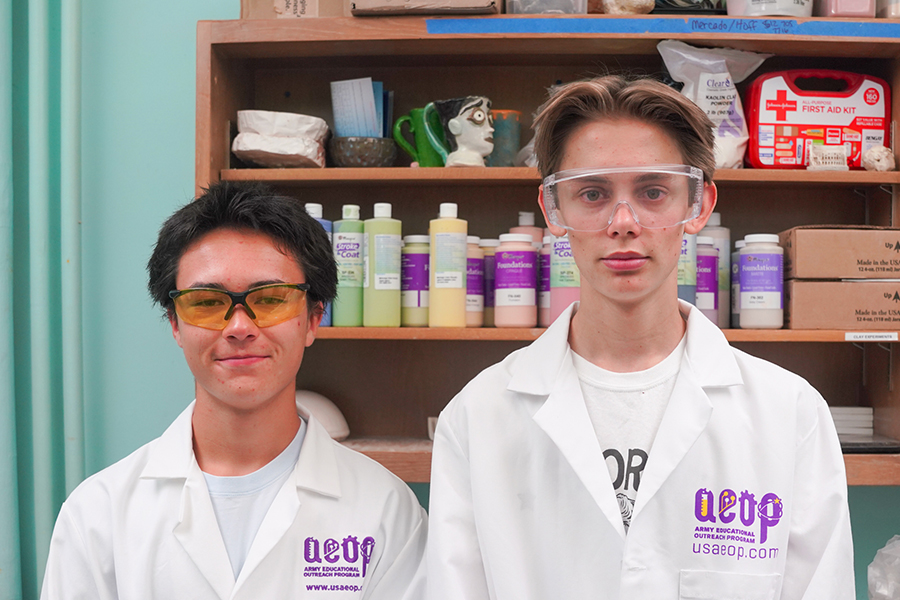

Article: published by Gray Hughes from South Dakota Mines. Pictured: High school students Ian Grinager and Aaron Letner (pictured) were the two participants in the Army Educational Outreach Program (AEOP) at South Dakota Mines this past summer. Both got valuable, hands-on STEM experience working on actual research.

RAPID CITY, SD (Oct. 11, 2023) – Every summer at South Dakota Mines, high school students get the opportunity to participate in real research projects through the Army Educational Outreach Program (AEOP). These students get to spend their summers literally getting their hands dirty as they work on – and contribute to – real research projects happening at the university.

This year, two students got the opportunity to assist identifying local Black Hills minerals, including rock and soil samples, that would be viable in the process to create a ceramic clay body and coating.

“AEOP apprenticeships and fellowships help high school students gain the skills and experience you need today to prepare for the STEM careers of tomorrow,” says Katrina Donovan, Ph.D., lecturer in the Department of Materials and Metallurgical Engineering.

AEOP is a grant program through the U.S. Army that provides research experiences in STEM for high school students, says Donovan. Through this program, the Army sponsors research alongside scientists and engineers in world-class facilities, like the ones found at South Dakota Mines.

Donovan worked this summer with two high school students, Ian Grinager and Aaron Letner. Donovan explains that, after chemically identifying and collecting minerals of interest from around the Black Hills, Grinager and Letner used mineral processing techniques to turn the rocks into a powder.

After the crushing, Letner used the crushed minerals to create the ceramic body, and Grinager used them to create the coating that improved the durability of the finished product. They fired their creations at 1,000 degrees Celsius and then tested mechanical properties of each uncoated piece. To improve the mechanical properties of an uncoated piece, a ceramic coating was applied to the uncoated pieces. The ceramic bodies with the ceramic coating were fired a second time. Grinager and Letner measured the mechanical properties of the ceramic coating on the ceramic body.

Letner, in his junior year of high school, said he wanted to get involved in AEOP because it was an inclusive STEM program.

“I learned a lot about the mineral industries field and whether it was something I wanted to pursue later in life,” he says, adding that there is no downside to the program because it is an incredible learning opportunity. “Even if you think AEOP isn’t for you, apply anyways,” he adds.

Grinager, attending high school and dual-enrolling at South Dakota Mines this year, discovered the experience through his sister, who had previously participated, and he wanted to get involved because it looked like a “cool opportunity.” He notes that the summer session was successful, and he thoroughly enjoyed it.

“I got to learn about the scientific method in the real world,” he says.

He urges other high school students to participate in the program, adding that “Dr. D (Donovan) is a good boss.”

“This program is an awesome approach to explore a potential career pathway and meet other high school students interested in STEM while providing a great opportunity and resume-building experience to discuss when applying for scholarships or jobs,” Donovan says, adding that one AEOP student from last year, who now attends South Dakota Mines, was able to secure a paid internship as a first-year industrial engineering and engineering management student.

In addition to the U.S ARMY supporting the students and material costs, Donovan says that part of the research for this project was funded by the National Science Foundation (NSF) curriculum development award. As part of this grant, South Dakota Mines students and faculty/staff have access to open clay studio time on Fridays from 3 p.m. to 5 p.m. in the Mineral Industries Building, room 220.

National Science Foundation RII Track-1 Project:Expanding Research, Education and Innovation in South Dakota

National Science Foundation RII Track-1 Project:Expanding Research, Education and Innovation in South Dakota